The last decades have witnessed outstanding progress in our understanding of the basic physics of soft matter materials. At the same time, microfluidics has also undergone spectacular theoretical and experimental progress. The confluence of such major advances spawns unprecedented opportunities for the design and manufacturing of new soft mesoscale materials, with promising applications in tissue engineering, photonics, catalysis and many others.

COPMAT is targeted at making the most this opportunity through the pursuit of a single general goal: the full-scale simulation at a nanometric resolution of micro-reactors for the design and synthesis of new tunable porous materials. In particular, we shall focus on the microfluidic design of multi-jel materials, trabecular porous media and soft mesoscale molecules. We shall also explore new designs concepts based on unexplored microscale phenomena, such as the interaction between plasticity and nano-rugosity. The complex interplay between the highly non-linear rheology of soft materials and the main experimental control parameters leads to an engineering design of formidable complexity, characterized by a strong sensitivity of the macroscale material properties on the details of nanoscale interfacial interactions.

COPMAT will tackle this formidable multiscale challenge through the deployment of an entirely new family of multiscale techniques, centred upon highly innovative extensions of the Lattice Boltzmann method and its combinations with Immersed Boundary Method, Dissipative Particle Dynamics and Dissipative Voronoi Dynamics. The success of COPMAT will be gauged by its capability of inspiring and realizing the design of microfluidic devices for the synthesis of novel families of porous materials for bio-engineering applications. The new paradigm established by COPMAT for the computational design of soft materials is expected to extend well beyond the time-horizon of the project.

The soft glassy material rheology is highly peculiar in many respects. To begin with, it shows a non-linear relation between the applied stress and the resulting strain, often exhibiting yield stress, i.e. no flow below a given applied stress threshold. Yield stress plays a central role in controlling the occurrence of plastic events, i.e. topological rearrangements of the density configurations, which shape up the kinetic pathway of the soft materials towards their thermo-mechanical equilibrium through the release of stress and decrease of the interfacial area.

The interface dynamics is controlled by the competition/cooperation of several concurrent interactions; pressure, long-range hydrodynamics, near-contact capillary forces and viscous dissipation. At low surface/volume ratios (low volume fraction of the dispersed phase, say oil in water for the case of emulsions) this competition can be treated by suitable multiphase/component extensions of the Navier-Stokes equations of continuum mechanics. At high surface/volume ratios (low surface tension) however, different portions of the interface come in near-contact, thereby triggering the effects of the short-scale capillary and dispersion forces, such as disjoining pressure.

This is precisely the fundamental framework which COPMAT inscribes to. Interfacial complexity is significantly accrued once the effects of confining walls are taken into account.

How does the interface interact with solid walls? How does such interaction depend on the wettability properties of the flowing materials? How does it change in the presence of unwanted or engineered nano-corrugations? These are some of the fundamental questions which bear a key impact on the microfluidic design of new porous materials.

These crucial questions are investigated in full depth, by means of a new class of full-scale simulations, nano and macroscales (nm to mm), over a broad range of process parameters, such as liquid volume fraction, poly-dispersity of the initial conditions, size of the confining microfluidic devices.

Several works in the recent literature have reported successful achievement of microfluidic templated porous materials with a higher degree of regularity and improved performance as compared to, say, classical sponges. The design of such materials faces with numerous challenges, such as sustained production rate, as demanded by industrial applications, broad range of viscosities and polydispersity. The full-scale simulation of such devices at a molecular level will shed unprecedented insights into the complex physical mechanisms which control the macroscopic properties of these materials.

We plan to perform full-scale simulations of flow-focusing microfluidic devices aimed at generating highly regular bubble configurations of oil/water emulsions. The prototypical device consists of a planar flow focusing circuit, integrated within a microchip about 1 mm in length and 300 microns in width (see Figure from Costantini, et Al. J. Mater. Chem. B 2014, 2, 2290). The oil phase flows from the inlet chamber and mixes with the two streams of water from the top and bottom directions. Immediately downstream the channels which deliver the two phases, there is an orifice which forces the oil phase to inflate oil droplets in the outlet channel and release a droplet under the squeezing effects of the water cross-streams from above and below.

The typical size of the device is of the order of mm, with droplets diameter of the order of 100 microns. As a result, full resolution of the droplets requires a mesh spacing below 1 micron, mandating of the order of a billion mesh points for the full-scale simulation of the device.

Such resolution, however, falls short of capturing the details of the near-contact and contact many-body interactions between the droplets, which is where the crucial microphysics takes place. This is where special multiscale capabilities will be deployed. We shall perform an extensive set of simulations by varying the flow rates by changing the inlet velocity of the flowing phases and the size and shape of the microfluidic device, as well as surfactant concentrations, so as to identify the best operational conditions to deliver the most regular porous configurations.

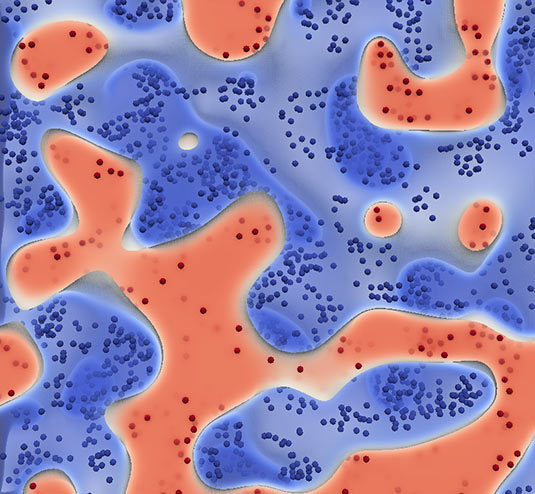

Bicontinuous interfacially jammed emulsion jels (bijels) are new multiphase soft materials in which two interpenetrating regions of immiscible liquids are stabilized by a jammed monolayer of colloidal particles, sitting at the interface between the two liquids. Such materials were first predicted via (Lattice-Boltzmann) computer simulation and subsequently realized in the lab, with mixtures of water and lutidine (W/L) stabilized via silica colloids with near-equal affinity to both species. Bijels properties are predicted to be highly tunable in terms of the size and volume fraction of the solid particles and perhaps also their shape, say ellipsoids versus spheres, over a broad range of scales.

We plan to perform systematic studies of the morphological and mechanical properties of the bijel metastable structure, i.e. pore size and elasticity as a function of colloidal size and volume fraction. More specifically, we shall investigate the effects of the particle radius and volume fraction on the morphology, pore size distribution and resulting mechanical properties of the bijels for different types of motifs.

For many applications, say tissue engineering, it is imperative to access pore sizes above 100 µm, which appears problematic with standard bijels. This can be achieved by a variant of bijels, known as bridged bijels, in which one phase contains a network of colloidal-bridged droplets. This dual morphology results from combined spinodal decomposition and nucleation and growth in a binary mixture containing neutrally wetting colloids with selective affinity for one liquid phase. Likewise bijels, the mechanical and morphological properties of bridged-bijels are highly sensitive to the physical-chemical properties and volume fractions of the colloidal particles.

The techniques developed in COPMAT will also permit to investigate the production and design a new class of exotic materials known as soft mesoscale molecules, assembled from cluster configurations of deformable oil-water double-droplets. In contrast to hard colloids, that assemble into unique configurations once the number N of colloids is specified, double-droplets with an aqueous core and oil shell prove capable of assembling new structures attaining higher packing fractions than rigid ones.

Such mesoscale molecules correspond to metastable configurations which owe their long-lived nature to the deformability of the droplets (anisotropic capillary forces) which disclose new free-energy landscapes unavailable to hard colloids. Of particular importance is a detailed computational construction of the phase diagram in the volume fraction versus the number of droplet plane (φ-N).

We shall investigate new design concepts capable of assembling larger exotic molecules than presently possible, thereby greatly facilitating the manufacturing of tissues out of such exotic molecules. We shall simulate the microfluidic setup for production of double water-oil droplets (see Figure from Guzowski, et Al., Phys. Rev. Lett. 2015, 114, 188302) and optimized variant thereof. Among the various parameters/phenomena under scrutiny to improve the current engineering design: i) long-range hydrodynamic interactions. ii) macro-geometrical parameters, iii) the ratio between the shell and core capillary energies, iv) nano corrugations.